Company history of Lithofin

Over 25 markets worldwide

Production and storage area with a total of 5,000 m²

Production capacity of 50,000 L/day

70 employees

Lithofin appoints Iberdin as exclusive representative in the Portuguese market for cleaning and surface care products

Lithofin introduces the modular ProBox system. The ProBox Protect (kitchen) module is developed for natural stone processing companies, where the high-performance impregnations are already professionally applied in the workshop during production. The ProBox Clean (kitchen) contains all the products required for the installation of kitchen worktops.

The ProBox Clean Tile (outdoor) module is the ideal counterpart for landscapers, tilers and professional outdoor installers.

The ProBoxes are available in Germany, Switzerland, Belgium, the Netherlands and France.

The installation of the double-walled tanks and the expansion of the production halls will also take place in 2023. The optimised warehousing, logistics optimisation and security in the stockpiling of raw materials contribute directly to securing the location in Wendlingen. By significantly expanding its raw material storage capacities, Lithofin sees an opportunity to meet the challenges of the future and to ensure stability in times of unpredictable price fluctuations and bottlenecks. Lithofin secures long-term competitive advantages through resource efficiency, the expansion of storage capacities, emissions reduction and waste minimisation. The aim is to continue to be a sustainable and responsible chemical company.

Lithofin develops four vegan home care products. With a basic cleaner, a sanitary cleaner, an all-purpose cleaner and a wipe care product, the main areas of daily cleaning are covered. Natural. Plant-based. Vegan. Containers made from 100% recycled plastic are used. The surfactants come from European production and no allergenic ingredients are used. The products were developed on the basis of the criteria of the Eco-Cert label in the development department in co-operation with the laboratory and product management in Wendlingen. The product line is now successfully positioned in Germany, Switzerland, Austria, France and Australia.

Lithofin AG successfully continued its internationalisation strategy and took over the Belgian and Dutch branches at the end of the year.

Lithofin complements the training and further education offering and has been offering live webinars in spring and autumn in addition to classroom training since 2020. The training portfolio is constantly being expanded and is very popular within the industry.

With the relaunch of autumn 2019 the functionality, user guidance and design of the website were developed further.

Lithofin globally introduces a new design and optimises international trade fair appearances

The office space was significantly expanded with a new building to create space for future expansion. In the new building, customer service, application technology, sales and marketing are located in close proximity to each other. Spacious seminar rooms for training courses and other customer events were created on the ground floor.

In order to take account of internationalisation, the company is renamed Lithofin AG.

In 2003, his son Garvin Stingel joined the management team and continues the internationalization process that began in 1978. Based on the principles of quality and service, the LITHOFIN brand is now active in more than 25 countries worldwide.

The first company in the industry to be certified according to DIN ISO 9001

Service and quality have been the focus of attention since the very beginning and are now officially audited and certified by external auditors.

Lithofin products get the design that is still typical today: the Lithofin corner

For a better overview, each product line has its own colour

Heinz-Peter Stingel combined the products under one brand name in 1979. This is made up of the Greek lithos (=the stone) and the English word finish: LITHOFIN.

The product range is offered in Austria, Switzerland and Greece.

After completing his studies in chemistry, Heinz-Peter Stingel took over his parents' business in 1974. He sharpened the product profiles and focused on ceramics, natural stone and artificial stone.

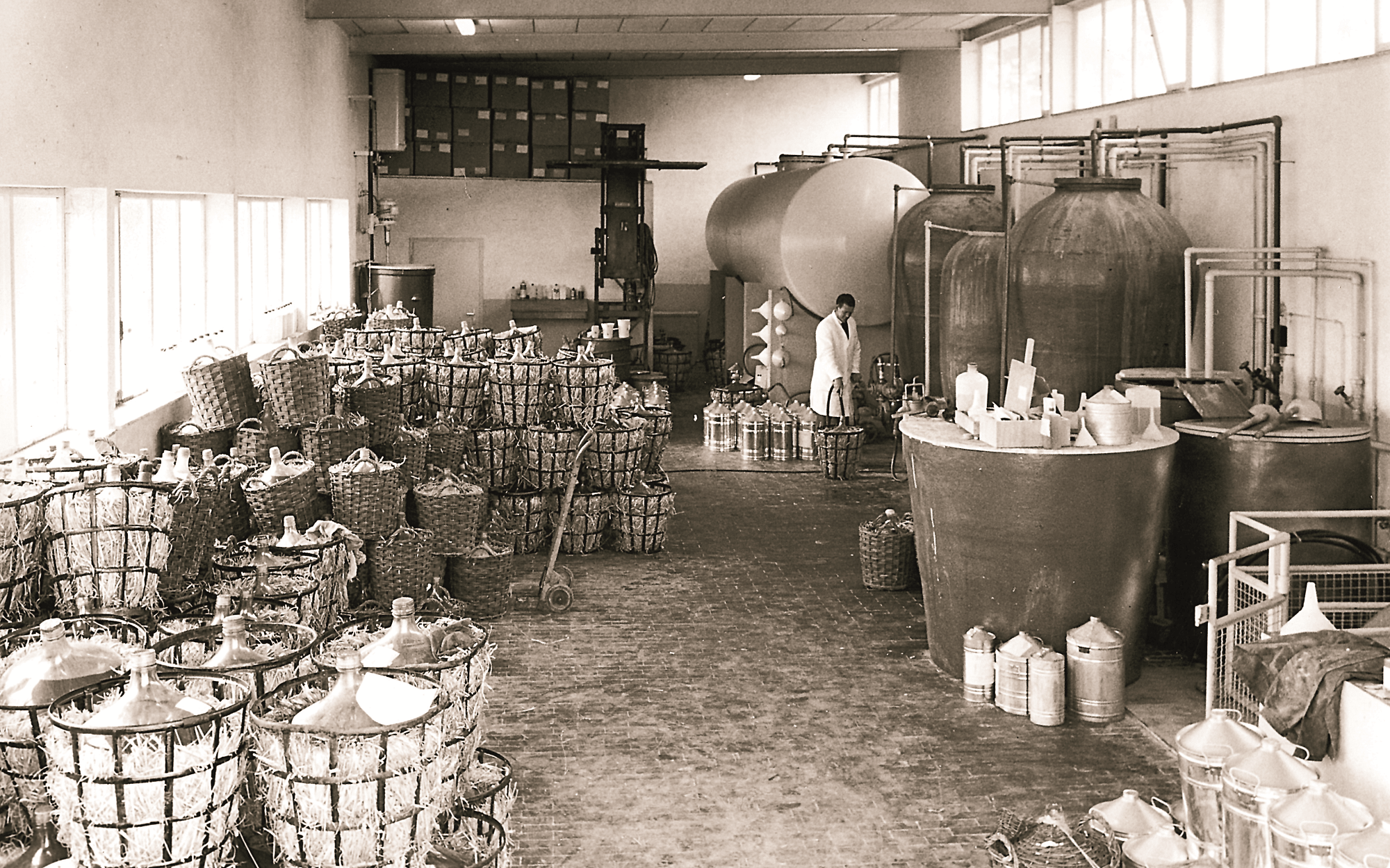

The demand within Germany increased rapidly and the foundation stone of the family business was laid. Soon the company moved to larger premises, to the present company premises in Wendlingen. There the development of an extensive product range began, which still inspires the customers today.

In 1953, Glaubrecht Stingel began producing a new type of cleaner in the idyllic town of Esslingen: ST57 KUKÜ.